Processing honey is NOT keeping bees

Processing honey is not in the same arena as keeping bees. While it is very true that to get a surplus honey crop, you had to do things like control swarming, restrict mite populations, and help colonies get through the winter, in the bright light of reality, once you take the crop from the bees, you enter an entirely different arena.

You now concern yourself with issues like kitchen floor protection, hot water supplies, honey strainers, and buckets improvised with draining gates. Concerns like these are totally different from traditional bee biology and bee management concerns. In fact, at this very moment, I know a few beekeepers who — over time — have grown into honey extraction specialists. They provide custom extraction services in exchange for part of the crop, and frequently for the wax cappings that accumulate during the process. The beekeeper gets their part of the honey crop back in new, clean, five-gallon buckets. All extracting concerns are literally sold to a honey processing specialist. Extracting honey cannot get any easier than that — but at a price.

Minimalist techniques for processing honey combs

Comb honey

To avoid extracting completely, just induce the bees to produce surplus honey in the comb. In this way, there is no extracting equipment required — at all. No cleanup. No sticky strainers. In fact, within our beekeeper world, there is an entire genre of beekeepers who manipulate their bees to produce honey in some comb format. Nothing is extracted. Cut comb, chunk honey, or section honey are vintage types of common comb products that the non-extracting honey producer may select.

If you are new to beekeeping, you must be wondering why all beekeepers are not comb honey producers. I see two immediate restraints. First, while comb honey might be technically simple to process, it is nearly always a challenge to produce. Secondly, and importantly, modern honey consumers prefer their honey in liquid form. For pouring, cooking, and reliquefying, liquid honey is now the common way to go.

Comb honey could be considered edible art. When produced correctly, it is a beautiful product. At some point, all beekeepers should give it a try, but liquid honey, as a human food product, is seemingly here to stay. Clearly, a full discussion of comb honey, its history, and its production parameters would be beyond the realm of this piece, but if you really do not want to deal with honey extracting hassles, consider the world of comb honey production.2

Draining honey

While I just suggested that you might want to consider producing comb honey as a non-extracting option, I hope you never consider “draining” combs as your primary extracting procedure. In the bee world, there are many cringeable moments and this is one of those moments.

Just simply uncapping the combs and then laying the uncapped side over a collection pan seems simple. In a perfect world, the uncapped honey drips out into the pan. After a few days, the frame is flipped, uncapped, and the other side is drained for a few days. But this process is not perfect. It is a very slow, inefficient process. The thin, liquid honey absorbs moisture from the open air and too often attracts pests like ants or flies. I only put in these few sentences here because I know beekeepers who have tried it. While a simple and inexpensive process, the resulting liquid honey crop is usually a low-quality product that is inclined to ferment.

Crushing comb to extract honey

In what is nearly a second cringeable moment, honey can be hand-squeezed or otherwise crushed from combs. Yes, this process can be just as sticky and messy as you are currently envisioning, but the technology could not be any simpler. And yes, a significant amount of honey remains in the crushed combs, but that crushed honeycomb can be melted into a beeswax cake.

I only have very modest experience in “comb crushing.” On occasion, I have accumulated capped honey in pieces of burr combs. These pieces were not large enough to justify activating the extractor, but there was enough there to justify a lesser effort. I used nylon bag paint strainers as crushing bags to prevent wax particles from blending with the liquid honey. I improvised a simple, temporary press made from two short boards and a hinge. Oddly for me, I did not take photos, but I think you get the picture — a little bit of extracted honey and a little bit of mess.3

A form of comb crushing — squeezing honey from comb cappings — has been, more or less, a procedure that beekeepers have employed for many years. Commonly, these keepers were crushing honey-soaked comb particles (cappings) to acquire liquid honey. Nowadays, rather than pressing cappings, wax spinners or specific baskets for retrofitting extractors are used to sling liquid honey from cappings and comb pieces.

But there are beekeepers who routinely press honey from actual combs. A classic example is thixotropic heather honey from Scotland. (ABJ readers, I need to say at this point that I have no personal experience with this honey or with its processing requirements. Honesty is the best policy — right?) I address this specific procedure because, should one want to acquire a honey press, these devices are commercially available to process honey in this fashion. Also, various comb crushing episodes are available on streaming video channels.

An Apicultural Aside …

At this point, I struggle not to wander from the theme of this article — Harvesting Honey — while unintentionally wandering toward the subject of Replacing Combs. The nexus to these two topics is if I destroy combs to harvest surplus honey, some say that I have done a good thing. I have removed aging wax combs that are possibly contaminated with environmental toxins and secondly, I will have removed combs and therefore, reduced future wax moth infestations. Yet, others of you will feel that I am causing the bees to do more work by rebuilding otherwise functional combs. Personally, I am presently in a transitory state — as they need it, I replace some of my combs some of the time. I hope that satisfies all — for the moment.

The more you have, the more you need

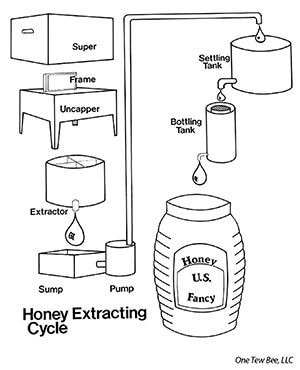

I cannot think of a single story of a beekeeper who bought a large extractor and then proceeded to search for beehives that would produce the honey crop that would need extracting. By far, most beekeepers acquire bees and secondarily acquire the equipment necessary to process the crop the bees produce. Ergo, keepers with only a few colonies who extract their crop only require a small extractor. Logically, beekeepers with larger numbers of colonies require more serious processing equipment. The more colonies you run, the more demand on your extracting line. The more you have, the more you need.

On the smaller spectrum of beekeeping

For the newer beekeeper with only a few hives, I have both types of news for you. You already know both categories. To put some parameters on this hypothetical beginner honey processor, suppose we say the beekeeper in question has two colonies and each colony has produced two medium supers of surplus honey — four supers total. Well, that’s good because it is not a big honey processing job at all, but it is also bad because — in a way — it is a big job. Yes, this is a classic conundrum.

It’s all in the details. With only four supers, you’re possibly going to extract in the kitchen or on the back screened porch. You will probably consider yesterday’s newsprint paper to protect the floor. That will not work well. While free and readily available, newspaper will tear and quickly stick to your shoes. Plastic film is slippery. That’s no good either. My good friend Charlie P. uses construction paper that he gets at building supply companies. He overlaps the edges and tapes the joints. While it is a lot of knee work, the heavy paper stays in place and protects the floor from wax and propolis. It withstands the traffic and is quick to clean up.

The smaller operator would love to have abundant hot water and screens on all open windows and doors. Ideally, there are no steps to the extracting facility. Good lighting and air-conditioning are great features. Uncapping pans and a couple of buckets will be needed. Ideally, there is a small, hand-cranked extractor and a heated knife at the work site.

For just four supers of honey, the beekeeper will need an extracting setup that could have been used to process many more supers. Yes, this small job will require the setup of potentially a much larger job, but the setup needs to be performed soundly at the outset. To make changes after you have begun extracting is a lot like putting on your veil after the stinging has started. You’re just a tad late.

So now, you have been there and done that

At some point, a small-spectrum beekeeper is ready to move to a higher level of honey processing. I was careful not to say that ….