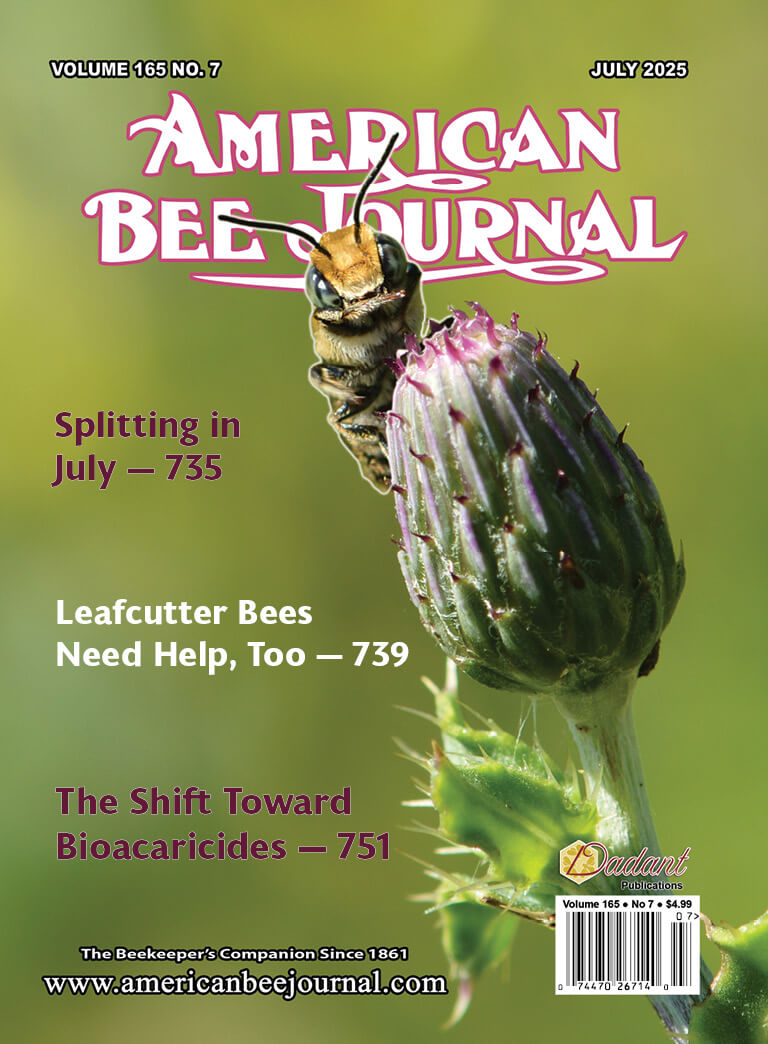

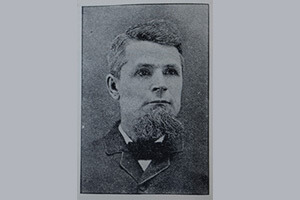

Although his name has drifted into obscurity, in the first half of the 1880’s, A. E. Manum was nationally known (see Figure 1). Manum was a beekeeper selling honey by the ton and manufacturing beekeeping supplies on a large scale in Vermont. His origins, however, were humble, and he did not come from a beekeeping family.

Augustine E. Manum was born in Waitsfield, Vermont in 1839.1 In the late 1840’s, his father apparently passed away. The 1850 census showed Manum residing with the Joselyn family, still living in Waitsfield, but parted from his mother and sisters. After being an apprentice in the harness trade, Manum moved to Bristol, Vermont around 1857. There he began his harness business at 18 years old. Manum would eventually give it up when his bee business became prosperous.2

In 1870, Manum read Quinby’s Mysteries of Bee-keeping Explained, by Moses Quinby, inventor of the bee smoker. The book sparked his interest in bees. Manum began beekeeping with four purchased hives, and he increased his hive numbers and honey production. In 1885, he produced 44,000 pounds of section comb honey, averaging 93.25 pounds per colony. That honey production occurred over a 12-day basswood nectar flow. Eventually Manum would surpass 700 hives in eight apiaries1 (see Figures 2 and 3).

Manum manufactured bee equipment with his distinctive designs. Historical items related to Manum are exceedingly difficult to find. However, I have been lucky a few times. To see the original hives, Figure 4 shows Manum’s hives with their numerous peaked roofs on a hillside.1 I also wanted to know how Manum used his hive. Since Manum manufactured and sold his hives, his catalogs, although very rare, provided a wealth of obscure details. Figure 5 shows his 1881 catalog. The hive on the cover is the outer case, which appears as a city of hives ascending the hill in Figure 4.

Figure 6 shows a miniature version of Manum’s outer case with its distinctive gable roof. This little hive was a salesman sample hive, a small portable “model” used to promote and sell the hive. Originally, the rest of the scaled-down hive, brood frames, etc. would have probably been inside the outer case, just like in the full-size hive.

Figure 7 of the 1881 catalog shows the “inner” hive, where the bees would reside. Above the extra steep alighting board were the brood frames. Around the brood frames was an inner wall. From his catalog, the Manum hive had a three-inch spacing between the outer case and the interior wall around brood frames. Manum filled this space around the brood frames with insulating chaff for the winter, which could have been sawdust, cut straw, or shavings from a wood plane. I know about similar hive designs from the early 1880’s in the northeast, which helps to fill in some gaps on how Manum may have used his hive (details missing in the catalog). A chaff tray most likely went above the frames for top insulation during the winter and to absorb moisture from the bees. Notice in this arrangement, the bees would winter only on one set of brood frames, as a single story hive in modern slang. Manum’s brood frames were only 9 ½ inches deep.

For honey production, Manum’s hive originally was meant for producing section comb honey (extracted honey came later). Comb honey section boxes received detailed description in Manum’s supply catalogs. Section boxes were labor intensive for beekeepers to assemble, much more than the modern one-piece design, where the beekeeper folded three corners and pressed together the finger joints (small dovetails) of the fourth corner. Manum made a four-piece section box where all four sides had finger joints. Thus, all four corners had to be assembled (glued and pressed). This section box was thought stronger than a four-piece section just nailed together or one-piece section folded together (in the modern way). Manum sold the very popular one-pound section box, 4 ¼ square (still used today), and other sizes, for example a larger section box that held two pounds of honey.

The section boxes were held tightly in a row, called a clamp. The hive in Figure 7 has three clamps on it. The number of section boxes in a clamp seemed to vary with its design and size of the section box. In addition, some kind of separator (partition) was typically between the section boxes, usually a thin piece of wood. The Crane clamp had tin separators between the section boxes in one row. In addition, the Crane clamp seemed best for the large two-pound sections shown in Figure 7. According to a price circular in 1885, Manum’s Bristol clamp was recommended for smaller one-pound sections. That clamp had two rows of eight sections for …

Photo Caption

A. E. Manum.1